The Hiring Freeze Came First. The Robots Came After.

This is not just a vibes-based assessment: in May, the U.S. reported around 332,000 open jobs in transportation, warehousing, and utilities, plus another 400,000 in manufacturing. Wages are up, benefits are better, yet demand still outpaces supply.

PILLARS OF TOMORROW - A hopeful vision of Government, Technology, and Human Dignity in harmony

For centuries, visions of the future have been dominated by dystopian warnings—cautionary tales of power gone wrong. Five Pillars of Tomorrow offers an alternative: a governance model where transparency, collective wisdom, and advanced AI safeguard human dignity.

OSARO CEO Derik Pridmore's 2025 Robotics Predictions: AI-Powered Solutions and Practical Automation Take Center Stage

As we enter 2025, the robotics landscape is evolving rapidly. Derik Pridmore, co-founder and CEO of OSARO, a leading provider of AI-powered robotics solutions for industrial automation, shares his expert predictions for the year ahead.

Robots are the new normal - Humans should embrace, rather than fear, robot co-workers

According to a recent report from the World Economic Forum, 85 million jobs could be lost and displaced by new technologies in the next five years. It's no surprise that workers, particularly in manufacturing, worry how these developments will affect their jobs.

Smart Robotics: Revolution Is Motto, Efficiency Is Aim

It is only an imagination in which robots are behaving like humans and getting smarter day by day. However, the distance between imagination and reality has reduced considerably.

Flashy Cars: AVs Will Be Here Later Than Promised, Better Than You Thought

For a lot of people, the idea of trusting your life to a computer hurtling you down the road sounds foolhardy. The whole idea behind the autonomous vehicle is to eliminate human error and deliver zero street/road fatalities - awesome, but impossible.

Why robotics needs a radical reboot

Laboratory News: For artificial systems to behave anything like living systems we need to fundamentally rethink the standard view of what behaviour is all about says Dr Rupert Young

Be Polite to Machines!

Machines won't be receptive to emotional, snide, impetuous, plaintive, vague or rambling communication. The algorithms will gently correct our moods and keep inquiring, relentlessly reasonable - or push the matter off to be dealt with later because they're not getting a useful answer from us.

What Manufacturing Needs

U.S. labor statistics project we will be short some two million manufacturing workers in the next 10 years.

3 Cs of Communicating Change in RPA Context

A perception of threat and an atmosphere of impending doom is not exactly what organizations want RPA to herald. It is a positive step in creating leaner, efficient and productive business processes.

Brainstorm the Future

Robots will take our jobs and "move the cheese" for those seeking to replace those jobs. Simply referring to the old adages (Cars put blacksmiths out of work ... and they survived) will not suffice in modern times.

Preventing Your Robot Technology from Being Obsolete Tomorrow

While "future-proof" technology is realistically too much to hope for, savvy companies will choose manufacturers with a proven track record for long term thinking, look for inherent flexibility in their purchases and plan for the inevitable changes that are sure to come as technology advances.

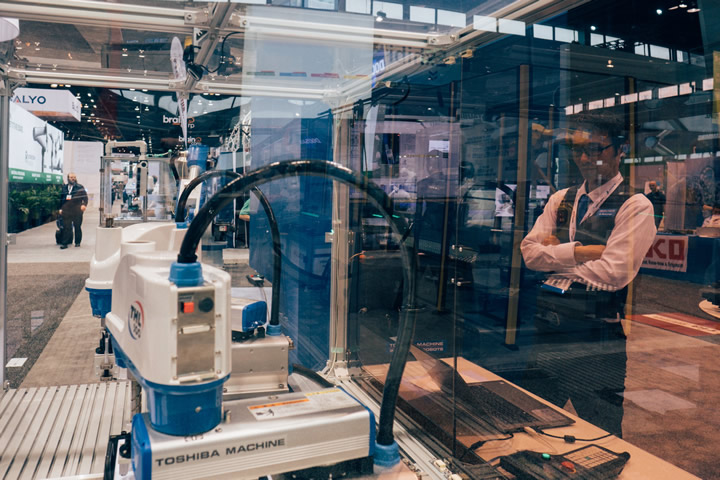

The Real Cost of Robotics

Realize that the arm is but a tiny part in the long list of equipment that had to be provisioned, installed, and configured in the name of your automation project.

Our Concept of an Open-Source Online Platform for Makers and Educators to Share Their Projects in the Robotics Makers Community

This is an outline plan to create and develop an open-source robotics community. If you have some ideas and want to share them, please let me know.

Discrete Manufacturers: Special Considerations for Robotics and Demand-Driven Supply Chain Solutions

Misalignment with suppliers is often caused by existing replenishment policies such as min/max order policy.

Records 1 to 15 of 28

Featured Product

DESTACO - Revolutionizing Industrial Automation

Looking for a reliable solution to enhance your automation process? Look no further than the DESTACO Robohand Grippers. These grippers are designed for the modern world of robotics, offering unparalleled performance and precision. Whether you need to grip fragile items, irregularly shaped objects, or heavy-duty components, the DESTACO Robohand Grippers have got you covered. Their modular design allows for quick and easy customization, ensuring a perfect fit for your application.

Robotics and Automation - Featured Company

Boston Dynamics

Boston Dynamics is the global leader in developing and deploying highly mobile robots capable of tackling industry's toughest challenges.