The global movement towards sustainability has put a spotlight on biolubricants as a great alternative to petroleum-based lubricants due to their ability to not harm the environment like petroleum-based lubricants do.

Engineering the Future of Lubricants: From Plants to Performance

Petrit Sheshori, Raj Shah | Koehler Instrument Company

Abstract

As the global push for sustainability continues to grow, biolubricants are becoming an increasingly popular eco-friendly alternative to petroleum-based lubricants. Since they are derived mainly from plant oils and animal fats, they are biodegradable, less toxic and reduce environmental harm. This paper explores some of the recent innovations and advancements in biolubricants like molecular engineering. Specifically they are engineering fatty acids in seed oils, like hydroxylated fatty acids, and wax esters. Some other advancements include adding nanoparticles directly to the biolubricants to enhance and develop biolubricants that are more efficient, stable, reduce friction, and wear resistance. However, they still face major challenges which do not allow them to become widespread. These challenges include high production costs, degraded performance in extreme temperature, and limited adoption due how hard they are to scale up. With continued progress biolubricants are becoming increasingly competitive and may very soon play a major role in shaping the future of sustainable lubricants.

Introduction

The global movement towards sustainability has put a spotlight on biolubricants as a great alternative to petroleum-based lubricants due to their ability to not harm the environment like petroleum-based lubricants do. A biolubricant is a sustainable lubricant that comes from biological and renewable sources including plant oils with some specific cases using animal fat. The purpose of using biolubricants is to reduce the friction and wear between two moving surfaces. Biolubricants are also the most eco-friendly lubricants due to how biodegradable they are and their low toxicity, leading to them being friendly for the environment. However, challenges like performance limitations and scalability barriers prevent the worldwide use of biolubricants. To address these challenges there have been many studies to improve biolubricants. For example, in 2016, the University of North Texas, in collaboration with the Biodiscovery Institute, has discussed the challenges to improve biolubricant developments by enhancing lubrication properties. Furthermore, the petroleum lubricant market was valued at $132.44B compared to the bio lubricant market that was valued at $3.44B, demonstrating the significant market gap and the changes that bio lubricants face when trying to achieve widespread popularity and adoption [1]. This paper will go over innovations in biolubricants, focusing mainly on plant-based feedstock development, like molecular engineering of oilseed crops, advancements in biolubricants, economic and sustainability benefits, and ways to make biolubricants overcome the limitations so it can become worldwide.

Innovations in Biolubricants

Molecular engineering of oilseed crops has emerged as a great strategy to enhance the performance and sustainability of plant-derived oils, especially in bio-bubricants. Scientists have used genetic tools, like molecular engineering of oilseed crops, to change the types of fatty acids produced in seeds and other improvements, like making them more heat resistant, increasing lubricity, and thermal stability. One example is, a 2023 study at the University of North Texas, on evaluating the effects of very long chain and hydroxy fatty acids was able to successfully engineer a crop to produce a very long chain and hydroxy fatty acids to seed oils [2]. The results from this experiment have shown to improve the biolubricant’s stability and lubrication in high pressure environments [2]. They have a 10-15% lower coefficient of friction, a 20-30% reduced wear scar diameter and a 15°C higher onset temperature, confirming improved stability and reduced friction [2]. A 2019 study at the University of North Texas experimented on biolubricants by using the nature-guided synthesis approach, which is when scientists study the natural oils in plants and use what they learn to design better biolubricants [3]. Specifically, they studied natural fatty acids in plants, and then using that information, they engineered oilseed crops to make similar molecules that improves heat resistance and the lubricant quality of the biolubricant [3]. These engineered oilseed crops reduced the coefficient of friction from 0.21 to 0.07, and had a viscosity of 1209 cP [3]. Another major innovation led by Huazhong Agricultural University and many other universities involved engineering seeds so the seeds can have hydroxylated fatty acids [4]. The result of adding the hydroxylated fatty acids to the oils is that it leads to a 4.1 fold increase in oxidative stability, increased its thermal stability to 300-450°C, and enhanced its lubricity in high temperature conditions [4]. Some other new innovations to crops is that they have also been engineered to produce wax esters [5]. Wax esters are oil compounds that are able to work as lubricants and can replace petroleum-lubricants in the near future [5]. These wax esters lead to the biolubricants having a low toxicity since the EC50 is greater than 100mg/L, 60% increase of biodegradation in 28 days, lowering the coefficient of friction to 0.05 and the wax esters are renewable sources. These examples show how molecular engineering has been used to improve biolubricants and make them more effective.

Recent Advancements in Biolubricants

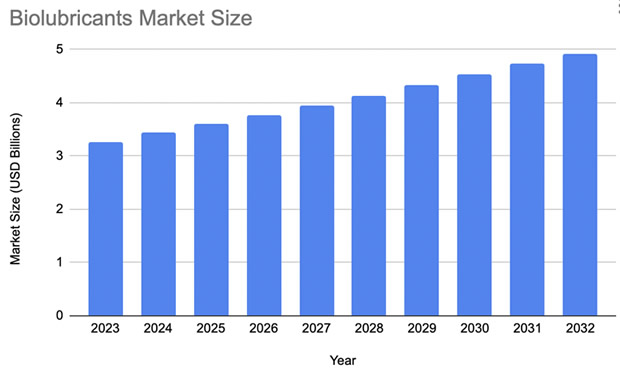

Besides molecular engineering, recent advancements of biolubricants over the last 3-5 years have improved their performance and made them a more viable alternative to petroleum-lubricants. Some of the biggest advancements in biolubricants have come with the recent technological advancements. For example, nanotechnology has led to the development of nanofluids and nanoparticles for biolubricants [6]. The polymer based nanofluids, which contain nanoparticles like MoS2, Cu, and graphene, reduce the friction and wear in biolubricants, which improves the performance, biocompatibility and durability of the biolubricants [7]. By using this, it also allows for self-healing and smart lubrication while still being eco-friendly [7]. Nanoparticles are also used to enhance the lubrication performance by reducing friction and wear of the lubricants [6]. They reduce friction by 26-34% and wear by 13-30% [6]. Besides nanotechnology there have been multiple advancements to improve the use of biolubricants. In a 2025 study led by Adewale George Adeniyi found advancements in biolubricant production. Recent advancements in chemical processes, including epoxidation, esterification and transesterification, have improved biolubricant production by enhancing the tribological performance, oxidative stability and efficiency [8]. These processes reduce friction, increase viscosity and improve biodegradability [8]. A November 2023 study led by Muhammid Ali Malik has focused on using algae as a sustainable feedstock option for biolubricants, instead of plant oils [9]. This is due to algae's potential to reduce the reliance on vegetable oils, which are very expensive, their high oil yield, biodegradability and the fact that they can grow in places that are not suitable for farming [9]. New efforts to improve the algae biolubricants production and stability are using better growing methods like enzyme processes and nanoparticles additives. All of these recent advancements do not only boost the performance of the biolubricants, but they also make them more globally sustainable, increasing the popularity of biolubricants compared to petroleum-lubricants. This is shown in the prediction of the biolubricants market size in the future as it continues to increase through every year.

Figure 1, Prediction of biolubricants throughout the years

Advantages of Biolubricants

Besides all of the advancements, biolubricants are increasingly popular due to the many advantages they have over petroleum-based lubricants. Their main advantage is that since they are made from renewable materials like vegetable oils and animal fats, this leads them to being biodegradable and less toxic to the environment [1]. This leads to biolubricants having little harm on the environment when they are spilled or disposed wrongly compared to petroleum-lubricants [1]. Besides how eco-friendly they are, biolubricants often lead to extended equipment life because of their superior lubricity and reduced wear [6]. This leads to biolubricants being more cost effective over time because of their longer service life and reduced maintenance costs [6]. They also have a low risk of fire, which reduces and improves the safety of the equipment [10]. Biolubricants also offer a greater lubricity and viscosity index compared to petroleum-lubricants, which improves the machine's efficiency and reduces friction and wear in specific applications [10]. Additionally, since they are made of renewable materials like plant oils or algae, you have a continuous supply of biolubricants compared to petroleum-lubricants who only have a finite number of resources [10]. These advantages position biolubricants as a promising, sustainable alternative to petroleum-based lubricants, particularly in environmentally sensitive applications. However, they still have multiple disadvantages, which prevent them from taking over the lubricant market.

Challenges and Disadvantages of Biolubricants

Despite all of these positives from biolubricants, they still have several challenges and disadvantages which limit their widespread usage. One challenge is they tend to degrade under high temperatures [2]. This is because vegetable oils have poor thermal and oxidative stability, which leads to their performance decreasing in very warm weather [2]. Biolubricants also struggle in cold temperatures because their minimum flow temperature is high, which leads to them being less effective in cold climates [8]. Another major disadvantage is that production costs of biolubricants are still higher than petroleum-lubricants [11]. This is due to the high cost of raw materials, and treatment processes that use chemical modifications or specialized additions are used, increasing the price significantly [11]. Some other concerns include the competition of food crops. This is because some biolubricants are made from edible oils, which leads to competition between industries as well as ethical and environmental concerns about how land should be used [8]. Biolubricants are also becoming more dependent on additives, like nanoparticles and antioxidants, to mitigate issues like poor oxidation state [10]. Lastly, one major disadvantage is even with all these new advancements, biolubricants are slow to become adopted across the world because of regulatory issues, limited consumer awareness, resistance from companies to switch over and the difficulty of obtaining expensive materials it is to produce these biolubricants [11]. All of these challenges and disadvantages show why petroleum-lubricants are still more popular than biolubricants and why additional improvements and innovations are needed.

Looking into the future, it seems that biolubricants are only going to become more and more popular. Future research on biolubricants is expected to continue making advancements on biolubricants. Some new ideas that scientists are exploring are non-food feedstocks, like algae and waste oils, to avoid competition with other industries in food stock [8].

Conclusion

Biolubricants present a sustainable and promising alternative to traditional based lubricants due to the fact they offer multiple advantages and improvements. Some of those advantages are being biodegradable, having lower toxicity, and enhanced eco-friendly compatibility. Through innovations like tailored fatty acids, adding nanoparticles like titanium dioxide, and improving the chemical and enzymatic processes, biolubricants have significantly improved their efficiency, stability, performance, and how eco-friendly they are, making them more competitive in every industry then what they used to be. Despite all of these positives, challenges like how they behave in very warm or cold temperatures, high production costs, and competition with food crops all limit the widespread use of biolubricants leading to petroleum-lubricants still being more popular. Future research is trying to address these challenges. With ongoing development in molecular engineering, eco-friendly processing, and improved efficiency, biolubricants are slowly gaining a key role in the future of lubricants.

Dr. Raj Shah, is a Director at Koehler Instrument Company in New York, where he has worked for the last 25 plus years. He is an elected Fellow by his peers at ASTM, IChemE, ASTM,AOCS, CMI, STLE, AIC, NLGI, INSTMC, Institute of Physics, The Energy Institute and The Royal Society of Chemistry. An ASTM Eagle award recipient, Dr. Shah recently coedited the bestseller, “Fuels and Lubricants handbook”, details of which are available at ASTM’s Long-awaited Fuels and Lubricants Handbook https://bit.ly/3u2e6GY. He earned his doctorate in Chemical Engineering from The Pennsylvania State University and is a Fellow from The Chartered Management Institute, London. Dr. Shah is also a Chartered Scientist with the Science Council, a Chartered Petroleum Engineer with the Energy Institute and a Chartered Engineer with the Engineering council, UK. Dr. Shah was recently granted the honorific of “Eminent engineer” with Tau beta Pi, the largest engineering society in the USA. He is on the Advisory board of directors at Farmingdale university (Mechanical Technology), Auburn Univ (Tribology), SUNY, Farmingdale, (Engineering Management) and State university of NY, Stony Brook (Chemical engineering/ Material Science and engineering). An Adjunct Professor at the State University of New York, Stony Brook, in the Department of Material Science and Chemical Engineering, Raj also has over 700 publications and has been active in the energy industry for over 3 decades. More information on Raj can be found at https://shorturl.at/JDPZN

Dr. Raj Shah, is a Director at Koehler Instrument Company in New York, where he has worked for the last 25 plus years. He is an elected Fellow by his peers at ASTM, IChemE, ASTM,AOCS, CMI, STLE, AIC, NLGI, INSTMC, Institute of Physics, The Energy Institute and The Royal Society of Chemistry. An ASTM Eagle award recipient, Dr. Shah recently coedited the bestseller, “Fuels and Lubricants handbook”, details of which are available at ASTM’s Long-awaited Fuels and Lubricants Handbook https://bit.ly/3u2e6GY. He earned his doctorate in Chemical Engineering from The Pennsylvania State University and is a Fellow from The Chartered Management Institute, London. Dr. Shah is also a Chartered Scientist with the Science Council, a Chartered Petroleum Engineer with the Energy Institute and a Chartered Engineer with the Engineering council, UK. Dr. Shah was recently granted the honorific of “Eminent engineer” with Tau beta Pi, the largest engineering society in the USA. He is on the Advisory board of directors at Farmingdale university (Mechanical Technology), Auburn Univ (Tribology), SUNY, Farmingdale, (Engineering Management) and State university of NY, Stony Brook (Chemical engineering/ Material Science and engineering). An Adjunct Professor at the State University of New York, Stony Brook, in the Department of Material Science and Chemical Engineering, Raj also has over 700 publications and has been active in the energy industry for over 3 decades. More information on Raj can be found at https://shorturl.at/JDPZN

Petrit Sheshori is an undergraduate student of engineering at Stony Brook University. He is also a member of a thriving petroleum research internship at Koehler Instrument Company where he regularly contributes to the petroleum and energy research industry.

Reference Page

[1] Bio-lubricants Market Share, Size, Trends, Industry Analysis Report, By Base Oil Type (Vegetable Oils, Animal Fats, Others); By Application; By End-Use; By Region; Segment Forecast, 2022-2030, (2021).

https://www.polarismarketresearch.com/industry-analysis/bio-lubricants-market

[2] R. Al Sulaimi, A. Macknojia, M. Eskandari, A. Shirani, B. Gautam, W. Park, P. Whitehead, A.P. Alonso, J.C. Sedbrook, K.D. Chapman, Evaluating the effects of very long chain and hydroxy fatty acid content on tribological performance and thermal oxidation behavior of plant-based lubricants, Tribology International 185 (2023) 108576.

https://www.sciencedirect.com/science/article/abs/pii/S0301679X23003638

[3] T. Romsdahl, A. Shirani, R.E. Minto, C. Zhang, E.B. Cahoon, K.D. Chapman, D. Berman, Nature-Guided Synthesis of Advanced Bio-Lubricants, Scientific Reports 9 (2019) 11711.

https://www.nature.com/articles/s41598-019-48165-6

[4] A.M.T. X. Li, A. Shirani, J. Ling, L. Busta, R. E. Cahoon, W. Zhang, Z. Li, K. D. Chapman, D. Berman, C. Zhang, R. E. Minto, E. B. Cahoon, Discontinuous fatty acid elongation yields hydroxylated seed oil with improved function, Nature Plants (2018).

https://www.nature.com/arti cles/s41477-018-0225-7

[5] A. Shirani, T. Joy, I. Lager, J. Lindberg-Yilmaz, H.-L. Wang, S. Jeppson, E.B. Cahoon, K. Chapman, S. Stymne, D. Berman, Lubrication characteristics of wax esters from oils produced by a genetically-enhanced oilseed crop, Tribology International (2020).

https://www.sciencedirect.com/science/article/abs/pii/S0301679X20300773

[6] “Biolubricants Market Size, Share, Growth Report, 2032.” Biolubricants Market Size, Share, Growth Report, 2032, Fortune Business Insight, 29 Sept. 2025, www.fortunebusinessinsights.com/bio-lubricants-market-104654.

[7] Rafat, Md Tanzim, et al. “Polymer-Based Nanofluid Bio-Lubricants for Artificial Joints: Improving Wear Resistance and Reducing Friction.” Science Direct, Mar. 2025, www.sciencedirect.com/science/article/pii/S2773207X24002136.

[8] K. O. Muhammed, I. K. Adegun, K. O. Iwuozor et al., "Advancements and challenges in biolubricant production for sustainable development," Chem. Afr., 2025. [Online]. Available: https://doi.org/10.1007/s42250-025-01443-5

[9] Malik, Muhammad Ali, et al. “A Review of Recent Advances in the Synthesis of Environmentally Friendly, Sustainable, and Nontoxic Bio-Lubricants: Recommendations for the Future Implementations.” Science Direct, Nov. 2023, www.med.upenn.edu/pmi/events/https-www-sciencedirect-com-science-article-abs-pii-s1047847720300046-via-3dihub.

[10] Fitch, Bennett. “Bio-Based versus Petro-Based Lubricants.” Machinery Lubrication, Noria Corporation, 28 Sept. 2021, www.machinerylubrication.com/Read/32087/bio-based-versus-petro-based-lubricants.

[11] Recent advances in harnessing bio lubricants to enhance tribological performance and environmental responsibility – Bibliometric review (2015–2024), https://doi.org/10.1016/j.clet.2024.100821, Open access, Cleaner Engineering and Technology.

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product