When faced with challenges of contamination and odor control, some indoor growers have adopted pressurized ventilation methods, manipulating positive and negative pressure to protect their grow spaces.

Grow Room Ventilation: The Pros and Cons of Positive vs Negative Air Pressure

Article from | Surna

Pressurized rooms are often designed for use in clinical settings as they can be helpful in quarantining infected or immunocompromised patients. When faced with challenges of contamination and odor control, some indoor growers have adopted similar pressurized ventilation methods, manipulating positive and negative pressure to protect their grow spaces.

Key Differences Between Negative Pressure vs. Positive Pressure

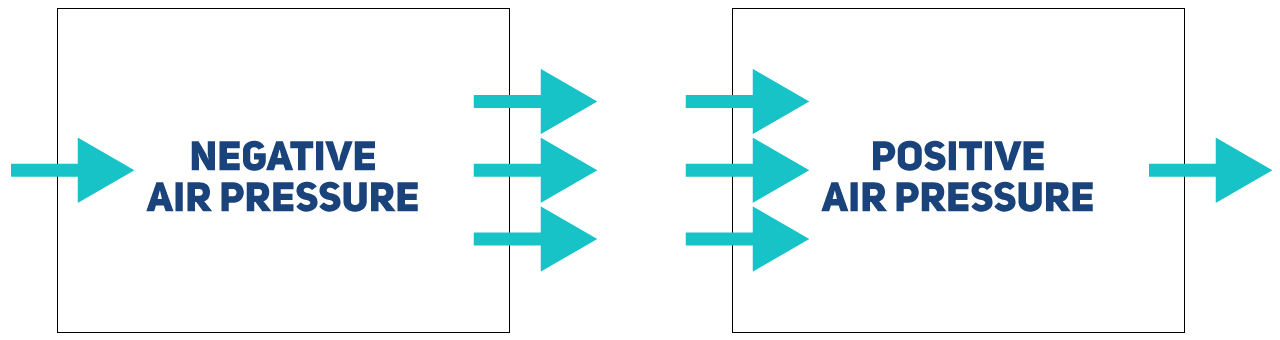

Have you ever felt a rush of air or the resistance of a suction seal when opening a door to a room? This is an example of how the difference in the pressure outside of a space and the pressure inside of a space can influence the airflow within. As with most things in life, air pressure seeks equilibrium. This means that lower air pressure will seek higher air pressure and vice versa.

When considering the key differences between negative pressure and positive pressure environments, there are two main factors: airflow rate and direction.

Airflow Rate

Airflow rate describes the amount of air that travels through your HVAC system. In the Imperial system, it is measured in cubic feet per minute (CFM) or cubic meters per minute (m3/min) in Metric. In order to pressurize a grow room, your ventilation system must maintain a pressure differential, meaning that there is either more or less air being exhausted than being supplied via outside air resulting in either a positive or negative room pressure overall. Mechanical engineers can estimate your air pressure differentials when designing your HVAC system.

Direction

Direction, as it relates to negative and positive pressure, refers to the net airflow. This is the difference of supplied air minus exhaust air. With negative pressure ventilation, the net airflow is negative. Conversely, a positive net airflow will result in a positive pressure.

How To Choose Positive, Negative, or Neutral Pressure Ventilation Systems

There are pros and cons to all types of ventilation. Manipulating air pressure is more commonly applied with grow tents. In our experience, most commercial growers install outside air intake and exhaust systems for use as emergency ventilation to meet local codes or in case they want to flush a room with fresh air.

Work with your mechanical engineer to determine what type of ventilation system would best serve your unique needs. It is important that you work with a designer who has previous experience in indoor agriculture applications as they will provide knowledgeable insights specific to cultivating plants indoors.

What is a Negative Pressure Grow Room?

Negative pressure is created when more air is being exhausted (removed from the space) than is being supplied. Because the pressure is lower inside the grow space than outside, it will create a suction effect which is useful for containing the air within.

Pros Of Negative Pressure in Grow Rooms

In cannabis applications, negative pressure is great for keeping things in, which makes it helpful for odor mitigation. While odor leakage may be minimized with this ventilation method, the air must still be properly filtered before being exhausted into the environment to maintain odor control compliance.

Creating negative pressure is particularly beneficial for home-growers using grow tents since isolating the air within the tent helps to make it easier to maintain the climate within the grow space.

Cons Of Negative Pressure in Commercial Grows

The suction effect of negative pressure will suck in the air from any air leaks or gaps. To minimize risk of contaminants, take special care to properly seal your room especially near doors, windows, outlets, and other potential gaps.

What is a Positive Pressure Grow Room?

When you introduce more air into your room than you remove, you create a positive air pressure. The pressure of the incoming air will force the old air out of the room through the exhaust fan, gaps in doors, windows, walls, outlet covers, and any other crack or opening.

Like with a cleanroom, positive pressure is used in grow rooms where the priority is keeping any possible germs or contaminants out.

Pros Of Positive Pressure in Grow Rooms

Positive pressure ventilation creates a barrier of entry for pathogens, pests, and other contaminants as the high pressure air will meet outside, low pressure air with force.

Cons Of Using Positive Pressure in Commercial Grows

On the other hand, positive pressure rooms can make it more difficult to mitigate odor pollution for cannabis cultivators. Carbon filters can help remove some of the odor from your exhaust air, but they are not 100% effective. If you are unable to properly clean your exhaust air, you may face complaints from neighbors, or worse, legal ramifications for failure to meet odor control compliance standards.

Sealed Grow Room Environments

A totally sealed grow room can be more difficult to construct. As discussed, to avoid risks of contamination or odor pollution, you should take care to properly caulk and seal potential gaps and leaks. However, the HVAC system you choose will also contribute to how sealed your environment is.

At Surna, we like to design systems that can operate at whichever condition the owner desires. While some operators may opt to pressurize grow room either positively or negatively at certain times, most commercial grow facilities operate at or near neutral pressure. This is because many commercial-scale operations prefer HVAC designs that do not share air with the outdoors. During neutral pressure operation, the air is conditioned and recirculated rather than being supplied and removed through intake and exhaust fans.

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product