This article will look at the top-end solution in terms of accuracy and repeatability, and the applications that benefit from a motion control solution that has achieved quantum-sized improvements in the precision achievable across numerous applications.

Applications of Nanometer-Level Precision Motion Control Solutions

Applications of Nanometer-Level Precision Motion Control Solutions

Walter M. Silvesky | ALIO Industries, Inc.

"Industry is driven today by the quest for the smaller parts and components often with sub-micron features, and more accurate, reliable, and repeatable manufacturing processes. Crucial to many exacting applications requiring nanometer-level accuracy and repeatability are best-in-class motion control solutions. This article will look at the top-end solution in terms of accuracy and repeatability, and the applications that benefit from a motion control solution that has achieved quantum-sized improvements in the precision achievable across numerous applications."

Walter Silvesky, Vice President of Sales, ALIO Industries

Discussion of the most precise motion control solutions inevitably leads to a focus on the numerous hexapod options that are available to industry today. However, it is easy for manufacturers to be confused as to the real accuracy and repeatability of these motion control systems through a mixture of supplier hyperbole, and also in truth, a standardization and regulation environment that is not geared up to truly and effectively differentiate between precise, very precise, ultra-precise, and nanometer precise alternatives.

Precision is by its very nature a vague term, it means one thing to one person, one to another, and the lack of “precision” when using the word “precision” allows for at the best unhelpful, and at the worst deceptive claims to be made by motion control solution providers.

This article is written from the perspective that precision means nanometer precision, an accuracy measurement that is only relevant in industrial applications if it is 100% repeatable, not something that can be achieved 20% of the time. It is in the production of nanometer precision and highly repeatable motion control solutions that ALIO has existed since its inception nearly 20 years ago, making it unique in the motion control sector.

The Ultimate in Nanometer-Precise Motion Control

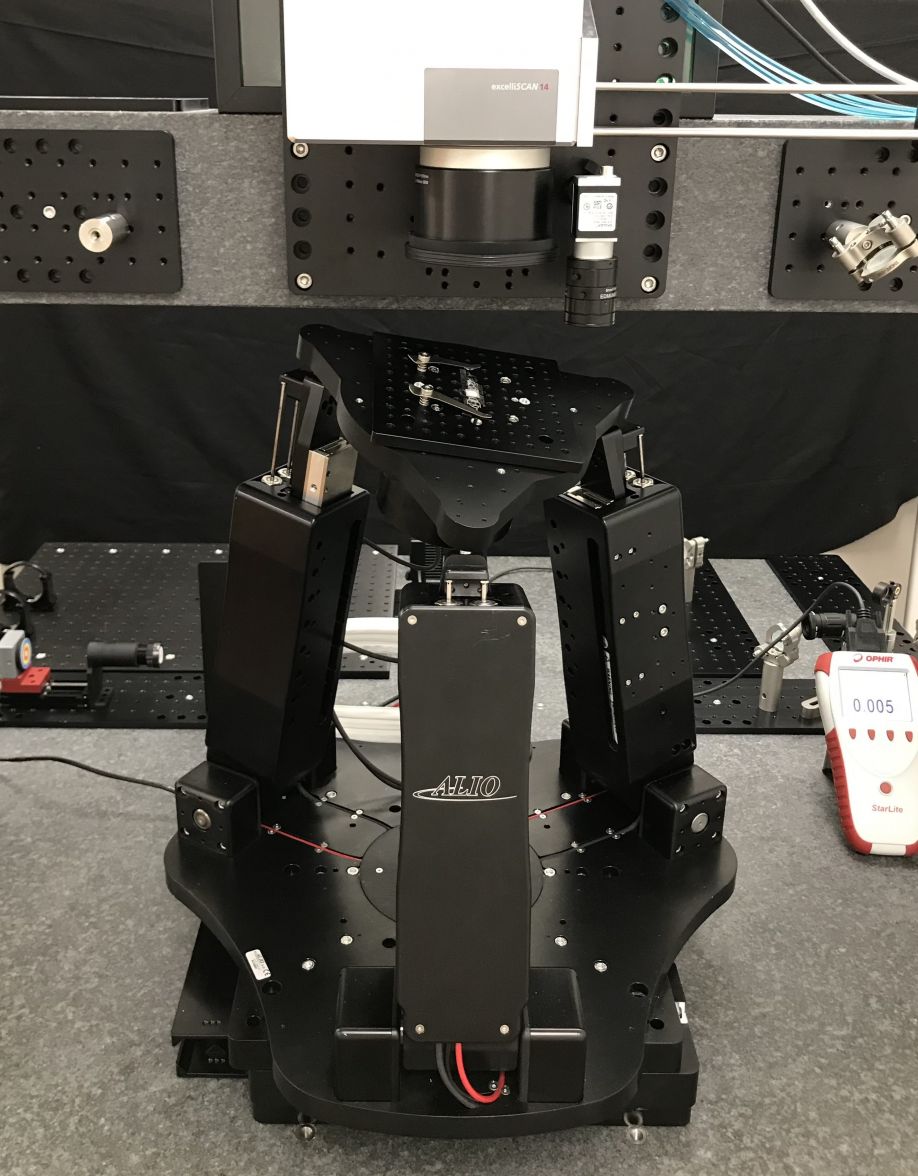

The latest addition to the range of ALIO Industries’ motion control solutions is the patented Hybrid Hexapod®. Traditional hexapod users face numerous restrictions in travel range, speed, and precision – factors that must be optimal to improve production processes and achieve the levels of efficiency and precision demanded by industry today. With the next generation of motion control devices exemplified by the Hybrid Hexapod®, manufacturers can achieve sub-micron and nano-levels of precision and increased accuracy.

Traditional hexapod structures are based purely on parallel motion. A Hybrid Hexapod® achieves its movement through the combination of both parallel and serial kinematic structures. Rather than using six legs to create motion, it uses a traditional X-Y stage, a tripod, and a rotation stage to provide 6 degrees of freedom (6DOF) in the device. The tripod’s parallel kinematic structure delivers Z-plane and tip/tilt motion, which is integrated with a monolithic serial kinematic structure for X- and Y- motion.

This combination removes previous application limitations and positioning errors synonymous with traditional hexapods. With the Hybrid Hexapod®, the precision of serial kinematics combined with the flexibility and compactness of a parallel kinematic device allows users to have all of the strengths of a 6DOF hexapod with none of its critical weaknesses. This key differentiator of the Hybrid Hexapod® opens the door for using a 6DOF positioner in a wide range of applications not previously considered possible. The Hybrid Hexapod® is therefore a true blue ocean technology, allowing manufacturers to achieve the impossible and stimulating innovation at every level.

The levels of precision and repeatability that characterize the Hybrid Hexapod® are such that existing standards for verifying precision accuracy and repeatability are not adequate. These inadequate existing standards give some motion control solution suppliers the latitude to claim nanometer accuracy, as they were basically designed for a 2D world.

ALIO Industries is working with NIST to improve this situation and give manufacturers confidence in the accuracy and repeatability claims being made. The company is doing this through the development of the measurement standard known as Point Precision®. Point Precision® gives a precision value that considers all 6 possible sources of error, or in other words a true 3D representation. The current standards can only represent precision one dimension at a time and make assumptions in linear repeatability and accuracy that the motion of a stage is straight and flat with all datapoints falling along an ideal line and ignoring the other five possible error sources. The current standards can measure the pitch, yaw, roll, straightness and flatness but without any consolidation of these error sources it is impossible for a user to get a result from the data where each of these error values is integrated which is where the significance of the Point Precision® becomes obvious.

Applications of the Hybrid Hexapod®

Using Point Precision® to “prove” the absolute precision, accuracy and reliability attainable through use of the Hybrid Hexapod®, opens up a vast array of applications for which it is now seen as the “go-to” motion control solution.

The umbrella under which all these applications sit is a requirement for nanometer-level control repeatably, with many of the applications involved rendered unfit for purpose if such motion control cannot be achieved. Here we will touch upon some of the key areas where manufacturers are using the Hybrid Hexapod®.

In general terms, aerospace users often incorporate the Hybrid Hexapod® in metrology systems. In precision optical elements, the tool can characterize, test, or measure optical components, and optical subassemblies. In precision assembly applications such as in the joining of optical image stabilization (OIS) modules to ultra-high resolution CCD arrays the Hybrid Hexapod® can serve as the motion device that manipulates the OIS module in 6DOF space in the alignment and bonding process. The high accuracy of the Hybrid Hexapod® decreases assembly time as the OIS can be properly placed into a package without any time-consuming post alignment measurements and re-alignment steps.

Active alignment of 4k lenses. 4K lenses require extraordinarily advanced material technologies, highly sophisticated manufacturing techniques, and precision assembly practices. Tolerance concerns in all degrees of freedom are paramount. Often the manufacturing techniques used to make the lenses result in positional inaccuracies, and this is where active alignment comes into the picture. The lens and sensor are aligned while projecting multiple targets through the lens and onto the sensor while the sensor is imaging. The active alignment machine continually monitors the modulation transfer function (MTF) at each of the target images until all MTF values are within acceptable limits. When all MTF values are sound, pre-applied adhesive is partially cured using UV, with complete thermal cure performed later. This allows the sensor to be aligned extremely accurately to the appropriate lens image plane. The absolute precision and repeatability of the Hybrid Hexapod® makes it ideally suited for control in such precision-oriented applications.

Fiber optic alignment. One of the most challenging tasks in photonics assembly is the positioning and alignment of optical fibers and components. Nanometer accuracy, exceptional resolution and extremely high stability are required when coupling laser light with the core of an optical fiber. Manufacturers of such items as lasers, amplifiers, connectors, filters, receivers, switches and other fiber optic components and modules need to minimize the amount of signal loss that occurs across the component-to-component or component-to-fiber junction. If alignment of the optical fiber and component is off just slightly, the product will be rendered useless. With packaging accounting for upwards of 50% of the cost of optical components, that's something manufacturers simply can't afford, and because of this, the Hybrid Hexapod® is routinely used to provide nanometer-level motion control for fiber optic alignment applications.

Metrology of optics and other complex shapes. Throughout the world, various types of metrology applications share a common need for increased precision. Markets such as life science, semiconductor, and electronics manufacturing rely on metrology instrumentation to ensure their process is completed correctly. The need for precision is further underscored when you realize the samples/products can be extremely small (i.e. human cell) as well as highly sensitive (i.e. touch-screen electronics). Having high precision, motion technology is key to ensure the application will be completed successfully, and hence the common use of the Hybrid Hexapod® to achieve such levels of required accuracy and repeatability in metrology applications.

Laser ablation processes. Laser ablation works by focusing a laser onto a substrate to remove material that is on its surface. The amount that is removed depends on the intensity, pulse length, and wavelength of the laser, as well as the material itself. Laser ablation has many benefits over more traditional methods which are often costly multi-step processes that are by their very nature time-consuming and inflexible. Laser ablation is a much more efficient, reliable and cost-effective method. Precision laser ablative processes require control of a combination of a number of motion characteristics, and the repeatable nanometer accuracy of the Hybrid Hexapod® coupled with the ability to give customers confidence of motion control in 3D through the use of Point Precision is key. Customers typically use the Hybrid Hexapod® for the laser ablation of silicon and glass.

Optics beamline assembly. In accelerator physics, a beamline refers to the trajectory of the beam of accelerated particles, including the overall construction of the path segment (guide tubes, diagnostic devices) along a specific path of an accelerator facility. This part is either the line in a linear accelerator along which a beam of particles travels, or the path leading from particle generator to the experimental end-station (as in synchrotron light sources, cyclotrons, or spallation sources). Beamlines usually end in experimental stations that utilize particle beams or synchrotron light obtained from a synchrotron, or neutrons from a spallation source or research reactor. Beamlines are used in experiments in particle physics, materials science, chemistry, and molecular biology, but can also be used for irradiation tests or to produce isotopes. Hybrid Hexapods® are used in such applications where the need for nanometer precision is a must.

Semiconductor inspection and manufacturing. Nanometer positioning and stability is a must in semi-conductor applications , with motion control solutions often needing to be able to operate in clean-room or vacuum manufacturing environments. Nanometer motion control is required from the get go in any semi-conductor application, even being used to perform a number of necessary processes on the base raw material for all semi-conductor wafers (silicon) onto which integrated circuits are embedded. Silicon for semi-conductor applications must be free of any defects , and must then be modified, patterned, and coated to provide the complex final chips. All this requires hugely accurate and repeatable motion control, and with the demand always being for better, smaller, and stronger products year on year, it is obvious why the Hybrid Hexapod® is used in the semi-conductor industry to ensure exacting motion control requirements.

ALIO’s Hybrid Hexapod® integrated into an ultrafast laser machining system with galvo scanner. The Hybrid Hexapod’s programmable tool center point allows control of the angle of incidence over the entire galvo scan field, enabling the processing of large features with side-wall Taper Angle Control.

Smart phone and small part assembly. For a product to be assembled successfully, it’s essential to move the right parts, to the right place, in the right orientation, at the right time. Motion control technology makes that happen. Populating circuit boards for smart phones and tablets, for example, places special demands when it comes to accuracy and speed, and demands the use of nanometer precision motion control solutions such as the Hybrid Hexapod®.

Precision CNC machining. The key advantage of using the Hybrid Hexapod® for any precision CNC machining operation is that it depends on mathematical algorithms not the mechanical relationship between components for accuracy and repeatability. The Hybrid Hexapod® allows CNC spindles to be driven almost in freeform fashion, allowing the manufacture of parts with geometric complexity impossible on conventional machining equipment. Tools can be directed in any plane required and with a huge reduction in the need to move the actual part being machined. With the hexapod, the tool never needs to leave the part being machined which also promotes better surface finish. The Hybrid Hexapod® is the most rigid and accurate hexapod on the market today, and while standard hexapods claim accuracy in the micron area, the Hybrid Hexapod® boasts nanometer repeatable precision for precision CNC machining applications.

MEMS assembly. Sophisticated motion control technologies such as the Hybrid Hexapod® enable MEMs manufacturers to make devices previously deemed impossible. Motion control and assembly issues are a barrier to MEMS development, and are overcome by the Hybrid Hexapod®. With its 6DOF, the Hybrid Hexapod® is able to perform important manufacturing and testing operations in MEMs fabrication, and is a spur to innovation and new MEMs product development.

Summary

The ability to control motion with nanometer repeatability elevates motion control to an enabling technology that stimulates innovation and new product development. ALIO exists in this environment and, through nanometer performing solutions such as the Hybrid Hexapod®, is finding uses at the cutting edge of numerous applications across various industry sectors.

About Walter M. Silvesky

Walter M. Silvesky is Vice President of Sales (domestic and international accounts) at ALIO Industries. Walter brings three decades of industry experience in precision automation to ALIO having spent more than 27 years with Newport Corporation leading multi-disciplined sales and marketing teams in developing key U.S. based and international accounts for industries including; semiconductor, laser machining, metrology, life and health sciences, aerospace and defense, flat panel display, data storage, and photovoltaics.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product