Artificial lighting is essential for growing plants indoors. This guide will walk you through the basics of understanding commercial horticultural lighting and things to take into consideration when shopping for fixtures.

A Guide To Horticultural Lighting

A Guide To Horticultural Lighting

Article from | Surna

There are thousands of choices for lighting available on the market today. These range in quality, efficiency, rebate eligibility, intensity, spectrum range, cost and more. So how do you begin to narrow down your choices and find the best option for your farm?

Start with the basics. You don’t need to become an engineer to make the right purchase. But you should have a basic understanding of what to look for in your lighting selection.

What is PPFD and PPF Efficacy?

PPFD stands for Photosynthetic Photon Flux Density, which is the amount of light energy available per square meter of leaf surface area. The higher the PPFD, the more light energy available to your plants. Plants use that light energy during photosynthesis to convert carbon dioxide into carbohydrates, which they then use to grow and reproduce.

PPF efficacy measures the energy efficiency of a light fixture. This is done by determining how much light (photons) it produces per watt of electricity.

When you’re ready to start shopping for commercial grow lights, understanding these measurements will help you compare different brands. Which light will be more energy efficient? Which fixture will produce the kind of output you need? Being able to read these measurements will help you answer those questions. You will also need these calculations when designing your lighting layout.

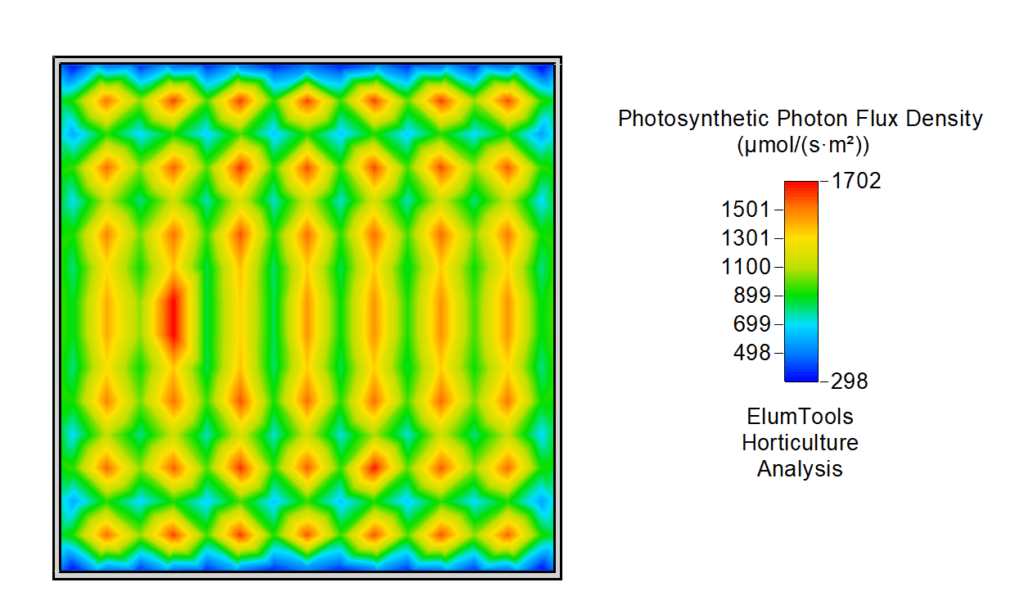

When making your lighting selection, some vendors will provide a PPFD model. These models show PPFD measurements at different locations across the plant canopy at a given mounting height. This gives you clearer insight as to how much light your plants will receive in similar conditions.

You should first understand the ideal PPFD for the crop that you’re cultivating, and ensure that the PPFD model for the light you’re considering provides that photon density. Consistency of PPFD is also very important. The PPFD model should demonstrate a fairly consistent photon density across the plant canopy. This way you can make sure that you will be able to maximize production out of every inch of your plant canopy.

How Does Color Spectrum Affect Plant Growth?

The color spectrum of light – namely blue, red/yellow, and even green – has been shown to encourage different growth responses in plants. One of the benefits of cultivating indoors is that growers are not reliant on the sun, and can control the light spectrums they expose their crops to. Manipulation of the light spectrum, in conjunction with other factors influencing plant metabolism, can produce a specific result in plant growth, harvest quality, and yields.

Blue light is the most prominent color of the spectrum. Blue light stimulates plant growth, and is best suited for the vegetative phase of growth.

Red and yellow light is often chosen for flowering plants as it promotes budding. This is because red is the easiest color on the light spectrum for plants to use to create energy through photosynthesis.

Green light is used by the plant, although not as efficiently as red or blue. Canopy penetration is limited without green light, however, and yields can suffer as a result. Incorporating sufficient levels of green light also allows growers to detect early signs of possible infestations by bugs, bacteria, fungi, mold, and other issues.

Lighting Types

While there are a number of lighting technologies in use in indoor cultivation, the two most prevalent technologies are HID and LED (this is true in both craft and large scale commercial operations).

HID

High Intensity Discharge (HID) lights are used in a variety of lighting applications, from parking lots, to office buildings, to car headlights, and also indoor agriculture. There are different kinds of HID lights available on the market, but the most common ones used for indoor growing are Metal Halide (MH) and High Pressure Sodium (HPS).

MH lights are typically placed in veg rooms since they provide more blue light, while HPS lights are usually used for flowering plants as they provide more red light.

HIDs have been used by growers for years with varying degrees of success. Some growers praise their HIDs for their reliability and intensity, while others have made the switch to LEDs retroactively for greater energy efficiency and flexibility. HID lights tend to have a lower initial cost, but they also produce light less efficiently than LED’s. So there is plenty of opportunity for cost-cutting over time via electricity bill savings or even through rebate programs for those who invest in LEDs.

LED

Light Emitting Diode (LED) lights are quickly becoming the go-to option for horticultural applications. These fixtures can vary in color or can offer broad or full-spectrum lighting, meaning they can emit all wavelengths of visible light. HID lights emit more light that is not useful to the plant, in addition to more waste heat, resulting in more overall waste than LEDs.

Also, the quality of light doesn’t degrade with lower wattage like it does with HID lights. This can be helpful to cultivators as they “harden off” young plants and increase lighting intensity over time, or to avoid moving certain plants from one room to another as they mature and require higher lighting intensity.

LEDs offer several other advantages over HIDs as well. For one, they eliminate the need to replace expensive bulbs, and they generally last longer overall, minimizing maintenance costs. Many LEDs come with dimming capabilities, which is great for both saving energy and allowing growers to have flexibility in their lighting schedules. LEDs also do not have a warm-up period, whereas HIDs do.

Overall, LEDs are more energy efficient and produce less heat than HIDs. According to Resource Innovation Institute, LED lights use around 60% of the wattage of a typical HPS lighting fixture.

The Next Step

Your lighting selection does not stop at finding the brand you like best. Your lighting vendor should also work with you to provide a more comprehensive lighting design. This involves PPFD modeling, proposing layout options, and taking other aspects into consideration like the mechanical system and electrical requirements.

Ready to look at your options? Surna Cultivation Technologies has partnered with BVV to provide lighting solutions with the lowest cost per micromole, and backed by an industry-leading 7-year limited warranty. With 15+ years of controlled environment agriculture experience, we are a reliable choice for lighting design, HVAC systems, architecture and floor plans, and more.

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product