BTM INDUSTRIAL IS HOSTING AN ONLINE SALE OF INDUSTRIAL ROBOTS ON DECEMBER 17-18, 2025

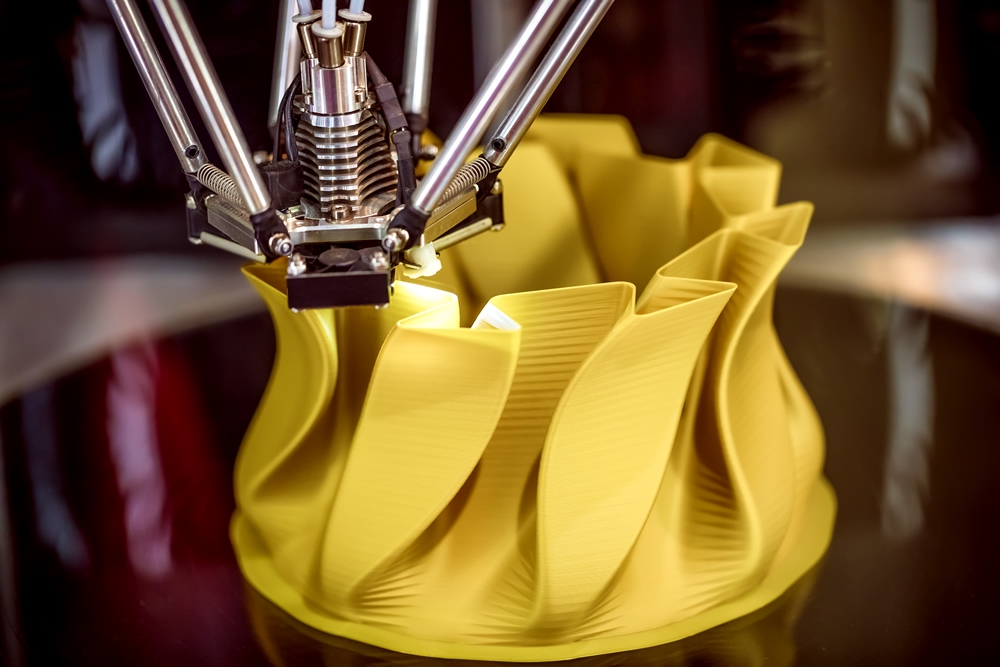

What are the motion control requirements for additive manufacturing machines?

What is Agentic AI and is it here to stay?

Automation Solutions Mergers & Acquisitions Update

SoftBank's $5.4B ABB Robotics Deal: Why IT Service Providers Should Treat Robotics as a Core Practice

Humanoid Robots to Drive Billions in Rod End Sales Over the Next Decade

How LAPP Rebuilt Its Inventory Process with Autonomous Drones

Sonair's ADAR 3D Ultrasonic Sensor

Optimizing Wheel Drives for AGVs and AMRs: What OEMs Need to Know About Motion Control

Automatic Visual Inspection: The Secret to Flawless Manufacturing Quality

How Rapid Repair Services Are Fueling a Competitive Edge in Automation

Moving Construction from Digital Design to Physical Reality

Fully Autonomous Vehicles for Repetitive Hauling in Manufacturing

Elmo Launches New Titanium Product Line and Platinum Servo Drives at SPS 2025, Redefining Limits of Motion Control

Designing Human-Centric Automation: The Next Evolution of Robotics in the Supply Chain

Records 31 to 45 of 3747

First | Previous | Next | Last

Featured Product

KNF - Automation Technology Requires Reliable and Durable Pumps

Robotics and Automation - Featured Company