Pest and disease control is perhaps the most critical and consuming activity for citrus growers. To keep these pressures in check, they employ a strategic and rigorous spraying schedule throughout the year.

Crop Management Company Improves Working Efficiency by 28% in Citrus Orchard Operations With Fieldin

Crop Management Company Improves Working Efficiency by 28% in Citrus Orchard Operations With Fieldin

Case Study from | Fieldin

Crop Management Company (CMC) is one of the largest and most trusted citrus orchard management companies in the San Joaquin Valley in California, overseeing field operations for over 6,000 acres of mostly citrus and some pistachio orchards from Fresno to Arvin. Owned and operated by fourth generation farmers in this region, CMC has deep roots and experience in the valley.

As Director of Operations at CMC, Alex Esparza is responsible for asset management and helping develop plans and practices for all of the activities carried out in the field. He’s officially been working at CMC for five years but has been around farming–and CMC in particular–for most of his life, as his father spent 28 years working at CMC.

“Being able to have a direct impact on the quality of our orchards is the most rewarding part of my role, but that doesn’t mean it’s easy. Making the right decisions out in the field requires access to all sorts of information, which technologies like Fieldin help provide.” Alex Esparza, Director of Operations, Crop Management Company

Fieldin helps CMC avoid mistakes and achieve better consistency in spraying operations

Pest and disease control is perhaps the most critical and consuming activity for citrus growers. To keep these pressures in check, they employ a strategic and rigorous spraying schedule throughout the year.

When CMC adopted Fieldin over 5 years ago, they were trying to gain better control over consistency in their spraying operations in citrus orchards. At the time, they had limited visibility over their spray applications, many of which occur through the nighttime hours to avoid extreme summer heats. They were stuck trying to wrangle reports from their field crews and driving around blocks looking for signs of errors. Sometimes they would uncover occurrences of skipped rows or incorrect speeds, but there was little confidence that they were catching everything that might be holding them back.

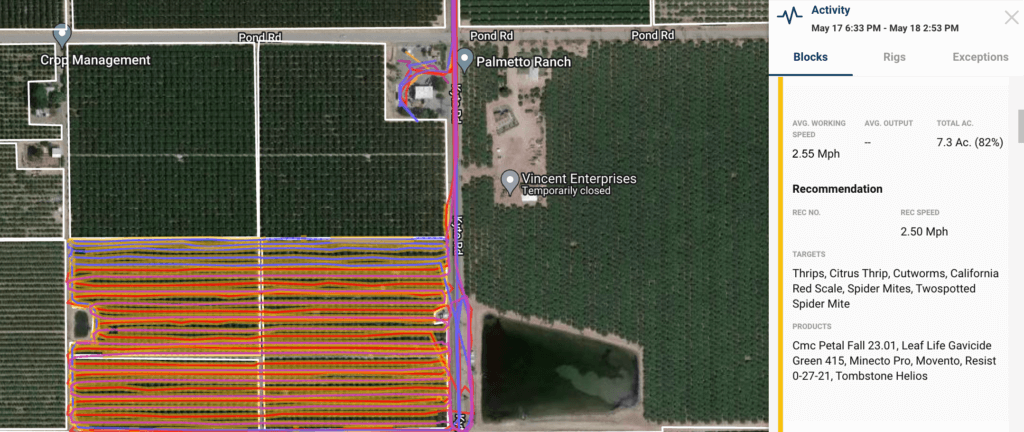

Once Alex’s team started using Fieldin for monitoring and reporting, they immediately realized the value of the solution. “Fieldin gives us a complete view of what our equipment is doing out in the field so we can confirm live that we are performing to our standards based on the planned tasks,” says Alex. “Fieldin has been helpful in creating more transparency and accuracy in our company.”

One particular feature that the CMC team has found beneficial is Fieldin’s ability to link their spray recommendation information to the execution of the spray task. This is helpful for real-time and historical data, as well as informing task planning based on Restricted Entry Intervals (REI) and Pre-Harvest Intervals (PHI).

CMC achieves 28% efficiency gain across all mechanized activities with Fieldin

Over the 5 years that CMC has been leveraging the data that Fieldin provides, they’ve made steady, significant efficiency improvements that have helped them do more with their resources. Across all of their mechanized activities, they have increased their overall shift working efficiency by 28%, which has helped reduce their total labor and machine costs. In spraying operations alone, they’ve improved their shift working efficiency 23% since they started using Fieldin.

To achieve these improvements, the CMC team has implemented processes whereby supervisors open the mobile app at regular intervals throughout the day to evaluate things like speeds, acres covered, and excessive downtime. This is in addition to system alerts that send notifications of critical deviations from pre-defined thresholds. Their mechanics also leverage the app to locate equipment in the field when repairs are needed.

More informed decisions helps make better farmers

When asked what single word he would use to describe Fieldin, Alex sums it up with practical. “The software is very easy to use in the field or in the office and helps bridge a gap of data that is needed between both field and office.”

Data has always been at the heart of farming, but modern solutions like Fieldin make it easier for growers to surface and harness the precise information they need to make better decisions.

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product