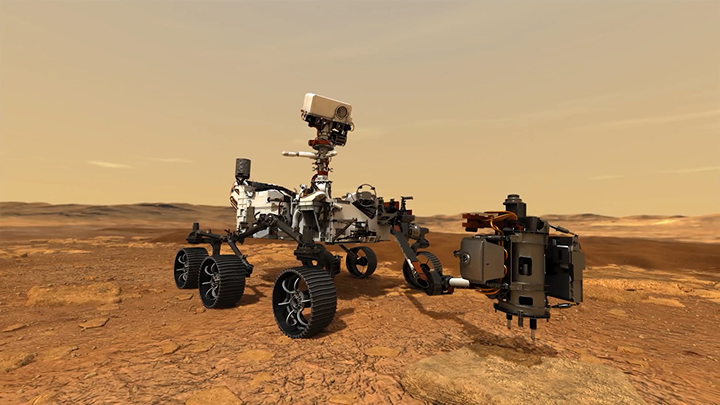

ATI Develops Space-rate Force /Torque Sensor for Mars 2020 Rover

JPL needed an automated system for collecting and handling space material as well as moving it through the indexing process. Engineers developed the Adaptive Caching Assembly, an application that resembles a pick and place operation commonly found on a factory floor.

Brain Corp Raises $36 Million to Meet Growing Demand for Autonomous Robots

Brain Corp, an AI company creating transformative core technology in the robotics industry, today announced it has raised $36 million in Series D funding to help meet the growing demand for autonomous mobile robots (AMRs) now on the front lines of the COVID-19 health crisis.

The Machines Are Taking Over Space

Faye Flam for Bloomberg View: And in terms of gathering data, we cant catch up to the robots, which have in recent years been plunging beneath Jupiters thick cloud cover and exploring the exotic moons of Saturn with their methane lakes and roiling ice geysers.

DARPA laying groundwork for growth in-space robotics

Sandra Erwin for Space News: DARPA pioneered the concept of using robots for in-space repairs and more recently invested millions of dollars in a public-private partnership with Space Systems Loral to build an autonomous vehicle for servicing satellites 36,000 kilometers above Earth.

How a One-Man Team from California Won NASA's Space Robotics Challenge

Evan Ackerman for IEEE Spectrum: In NASA's Space Robotics Challenge, participants had to command a virtual Valkyrie robot to perform a series of repair tasks in a simulated Mars base hit by a dust storm.

DARPA taps Boeing for unmanned reusable spaceplane

Ross Wilkers for Washington Technology: Boeing has emerged as the winner of a DARPAcompetition to design and test an unmanned reusable spaceplane.

Mission to Mars

Barrett and Draper Team To Harden the Ultraminiature Puck® Motor Controller for NASA JPL's Next-Generation Mars Rovers

WPI Robotics Team Has a Mission with Mars

-WPI team is a finalist in the NASA-sponsored Space Robotics Challenge;

-Team to program a virtual robot to perform critical tasks to repair a Martian habitat

NASA's new $1 million Space Robotics Challenge to prepare robots for Mars journey

Evan Ackerman for IEEE Spectrum: Last year at the DARPA Robotics Challenge Finals, NASA announced a new challenge for humanoid robots: the Space Robotics Challenge (SRC), which will “prepare robots for the journey to Mars.” Just like the DRC, the first stage of the SRC will consist of a virtual challenge, run in the Gazebo simulator, followed up by a physical challenge using NASA’s R5 Valkyrie robots.

As of yesterday, NASA has opened registration for the SRC, and we’ll take a look at the format of the competition, the challenges that teams will need to complete, and what they can take home for winning. Cont'd...

University of Surrey presents a roadmap of space robotics

ABIGAIL BEALL FOR MAILONLINE: Many people spend their childhood peering up into the vast expanse of the sky, dreaming of growing up to become an astronaut. But these dreams could be dashed as the idea of people venturing into space will one day become a distant memory, according to a report published today. Robots will eventually have enough capabilities to replace humans and other animals on space missions, experts have said. Many missions involving humans in space are dangerous and expensive. But for years robots have been sent to places humans could not venture, like the rovers venturing to the edges of our solar system. According to European Space Agency (Esa) Astronaut Roberto Vittori, who launched a paper on space robotics and autonomous systems, robots can help carry out these dangerous missions. Cont'd...

NRL Engineers to Lead Payload Development for Robotic Servicing of Geosynchronous Satellites

The Front-end Robotics Enabling Near-term Demonstration, or FREND, flight prototype robotic arm performs fully autonomous grapple testing. This testing demonstrates RSGS on-board processing's ability to track and guide a robotic arm to grapple a launch vehicle adapter ring (left) that is common to many spacecraft designs.

NASA's Modular Robotic Vehicle (MRV)

From NASA at the Johnson Space Center:

Records 1 to 12 of 12

Featured Product

ResinDek TRIGARD ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC (www.resindek.com) created the TriGard ESD Ultra finish for its ResinDek engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Robotics and Automation - Featured Company

MMP Inc. / MIDWEST MOTION PRODUCTS, INC.

The Leader in Rapid Prototyping of High-Quality Motion Control Solutions. MMP is actively engaged in the design, manufacturing and distribution of standard and custom motion control equipment, including fully reversible brushed and brushless DC gearmotors, motors with failsafe brakes and servomotors with feedback devices such as analog tachometers and encoders. We also provide fully-sealed IP-65 motor speed controls @ 12/24/48 VDC, AC~DC power supplies and a wide variety of 12/24 VDC linear actuators. If you need a sample right away, we can be a project saving convenience for you. We provide more than 8000+ released DC Gearmotor designs with cost-effective solutions for robotics and automation companies. These designs are unique and custom-built to suit the specific application requirements of the motion control projects.